We offer the following services:

CNC Milling

CNC Turning

Gear Hobbing

Precision OD Grinding

Thread Milling

General Machine Work

CNC Turning

Gear Hobbing

Precision OD Grinding

Thread Milling

General Machine Work

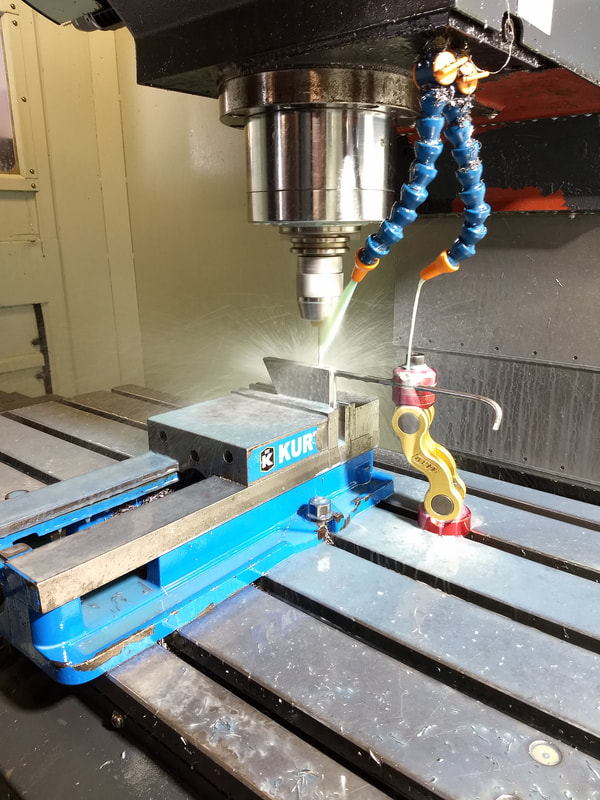

Why our CNC milling service?

We offer three-axis CNC milling. Our machines are programmed using state of the art CAD / CAM software. We can design your part, create toolpaths, and jump into production. This is faster than traditional programming methods, and reduces costly error. Machines like ours are capable of workpieces smaller than a quarter up to 1,320 pounds! They’re equipped with 24 tool, automatic tool changers, and 10,000 Rpm spindles for tough, high-speed machining jobs. Whether you need one part or a thousand, our mill department will adapt to your manufacturing needs.

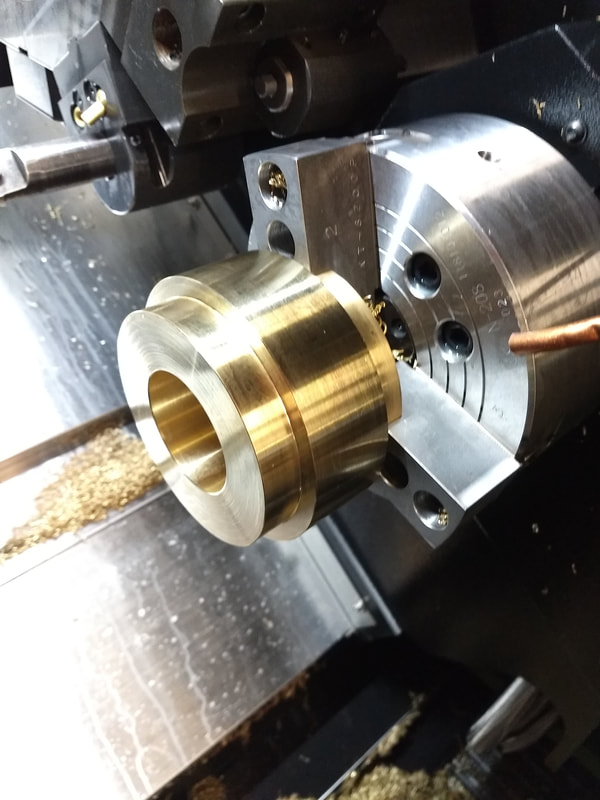

Why our CNC turning service?

Most lathes have two axes, our newest machine has five (X, Y, Z, B, and C). Why does this matter? It means your part can be manufactured complete in one setup. Normally, parts with complex milled, drilled or tapped features require subsequent operations on other machines. With live tooling, our lathe can drill, tap, and mill intricate shapes. The sub-spindle automatically runs the second operation. Our machine has bar-feeding capacity for high volume orders. The lathe can turn workpieces less than 1” up to 15” round.

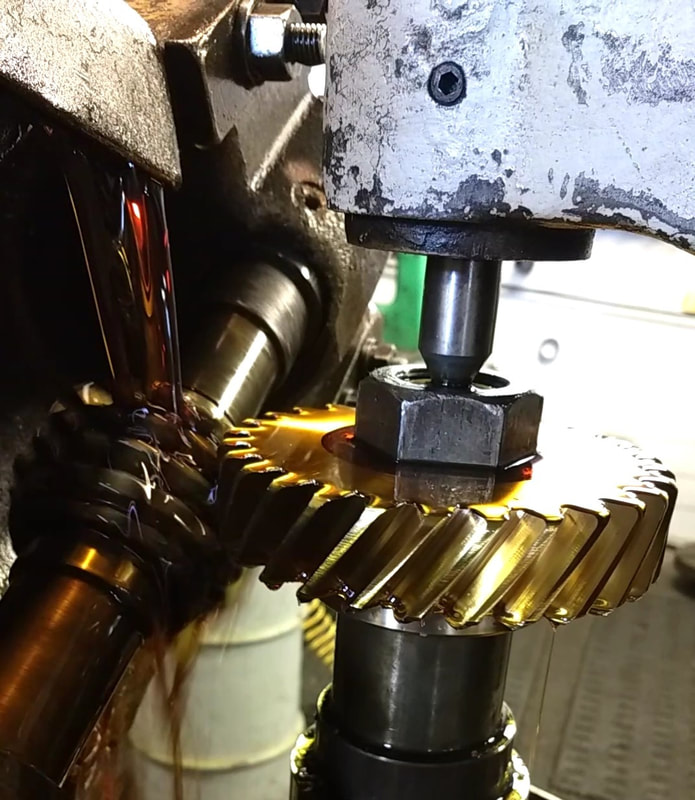

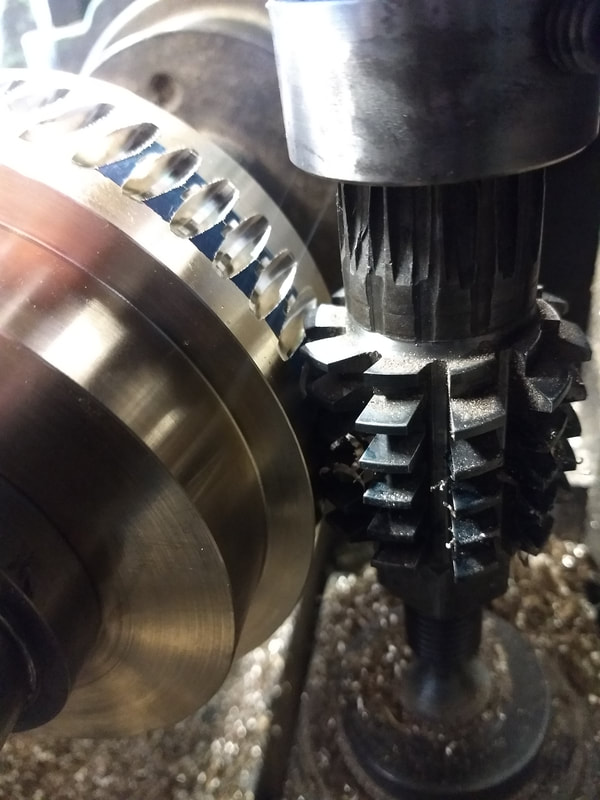

Why our gear hobbing service?

We have a large in-house inventory of hobs organized by base pitch. We probably have the hob for your job. Our knowledgeable machinists have experience with worm, spur, helical, sprocket, spline, and non-standard gearing. We can hob gears from about 1” in diameter up to 24”, and look forward to meeting your gear manufacturing needs.

Why our precision OD grinding service?

Blackhawk has been grinding parts for various industries for many years. Our machinist’s commitment to quality is excellent. We routinely grind parts to tolerances less than +-0.0003 of an inch hardened, or soft, and made from many different materials. Each part is inspected with industry standard equipment, carefully packaged with inspection reports, and shipped out.

Why our thread milling service?

While CNC machines are capable for thread milling, one of our machines was built for it. Our Pratt and Whitney Model “C” is capable of workpieces 6” in diameter up to 10’ long! It’ll cut inch, metric, left, or right-hand threads. We routinely cut worm shaft threads, and very accurate leadscrews. Our machine is excellent for manufacturing very long threaded parts.

Why our general machine work service?

Blackhawk has an arsenal of manual machines including Bridgeports, drill presses, a large radial drill, and manual lathes. Not all parts require a lot of machining. We regularly run batches of parts that require only tapping for instance. Whether a part, or a truckload of parts need tapping, drilling, or some combination of machining processes, our manual machine department is here to serve.